3D printing for the people?

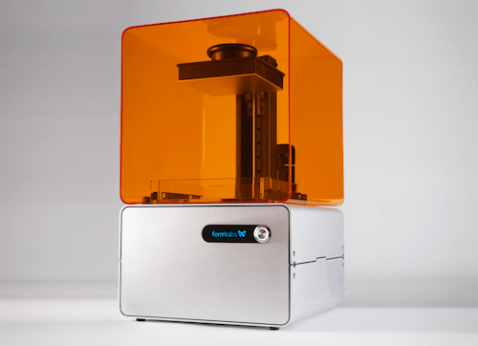

Crowd-funded via Kickstarter, FormLabs has taken a pretty big step toward making more accurate 3D printing something that’s accessible to any creative, from around $3,300.

Making 3D printing accessible in this way has the potential to transform industries, making it possible for relatively fast and easy product form prototyping and increasing the chance of the tech to spawn new enterprises. (Also worth a look is Solidoodle, which costs from $499, but may not be so accurate).

The future, the future

- Hobbyists may be keen on self-assembled model kit templates purchased online and printed at home, for example.

- The capacity to download templates for essential spare parts (albeit plastic) should have implications in many places.

- New classes of unique, collectible toys may even be possible. (Disney began messing with this last year).

These aren’t pie-in-the-sky notions, though like every new technology there’s a potential dark side: some US pro-gun lobbyists are reacting to proposals to limit US arms sales by working to develop 3D printable guns, with some success.

In a sense this proves the point, and the success of FormLabs and others in developing affordable 3D printers to bring the kind of quality you only before enjoyed at the high end to a wider market could begin a new wave of disruptive innovation.

Yes, there are limitations to what the technology can do for you today. We’re still waiting for metal and ceramic 3D print media at the lower end of this market — affordable 3D is presently confined to things you can print with thermosetting plastics. Another limitation is object size, which is generally limited to around 6-x-6-x-6-inches (unless you use state-of-the-art equipment).

Another problem is the resolution of the printer, which currently stands at around 0.1mm, which isn’t accurate enough for precision components, if that’s what you want to print. Though Formlabs promises much better accuracy than this (there’s an example of a tiny statuette printed using the system below).

Think on this: as 3D printing becomes more accurate and the scale of materials available to these devices grows, there’s got to be possibilities for entire products to be printed while you visit your local print shop.

Might this be the new face of retail, in which the patent for an object allows a manufacturer to distribute that object via high street 3D print shops, cutting both manufacturing costs and mitigating the environmental damage of transportation?

In theory raw 3D materials may be easier and more robust to distribute than the finished product they become, plus there’s a saving in inventory, warehousing and distribution costs. There’s an interesting take on this idea here. We’re a way from that reality today, as I explain below.

The crowning achievement of Formlab’s solution is that it uses a technique called extrusion, rather than stereolithography which most such printers employ. This means that while this solution costs more than low-end systems in this category, the results are more accurate.

That accuracy makes this a potential solution for architects, CAD design, product prototyping, education, animation, the supply of precision components and other industries we haven’t seen emerge yet. Not to mention artists prepared to dabble with Autodesk’s 123D iPad App.

Where is that puck, anyway?

This inevitably becomes a new area of exploration for Dreamtek customers engaged in the creative industries. You might want to dabble in what’s possible (without investing in the kit) using the Sculpteo service, which will print your models for a fee.

Will this technology change the world? Well, the hype’s promising, but there are some things in the way of such transformation: accuracy, the cost of resin and the time to print.

At $149/litre, resin costs are fairly high: this means 3D printing technology can’t yet fully meet its promise — sometimes it’s just cheaper to buy the thing you want, rather than print it.

However, the biggest challenge at this end of the 3D market is time. Solidlabs confirms that a 53mm Chess set rook takes two hours to print (though you’ll get 75 such Chess pieces from a litre of resin). This implies that printing a complete Chess set might take you 64 hours (sans board), and we don’t yet know how much energy that process will require or how much that might cost.

This suggests mass market implementation of printed products on your high street isn’t likely yet: but for creative users who need relatively fast output for their ideas, the momentum means a 3D print future isn’t only possible, it’s here.

That’s a good thing, because there are approximately 10 million users of 3D CAD software across the world, sharing use of just 30,000 professional quality 3D printers.

Despite which, before fully buying into the “3D printing will change the world” hype, it is worth considering the existing limitations of output size, available media, cost of that media, speed to completion and energy costs. We’ve a road to travel to that 3D future yet, but it might be worth taking a look to see where it’s going.

Unfortunately I don’t think 3D printing will make any kind of boom until you can make decent sized models for a good price. Once this boom happens though, it is going to be loud and it might just change everything.